Company Information

Changzhou RenBen Bearing Factory(Changzhou Global Bearing Factory)is a manufacturer specialized in Producing Various cam clutch, one way bearing, needle roller bearings,one way clutch, backstop clutch, overrunning clutch and other bearings with high technology.

Workshop

Manufacture Processing

Testing equipment

Main products

1. One Way Bearing

1. Overrunning clutch

for multiple-machine drives or to separate the iner-tia of masses of a driven machine from the driving machine after it has been switched off.

2. Indexing clutch

which turns a shaft step by step, thus achieving indexed material feed or a variable speed.

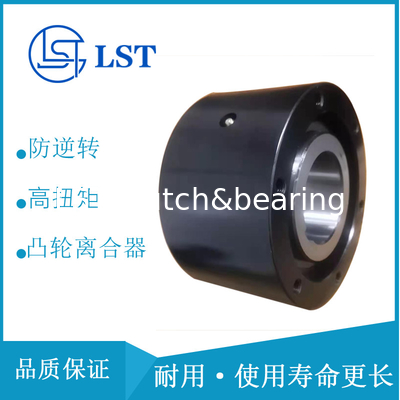

3. Backstop

to prevent a machine shaft turning backwards. In this case the overrunning clutch acts as a brake

2.Needle roller bearings

Applications:

Backstop

A Backstop application is where rotation

is allowed in one direction and stopped in

the opposite.

Application examples:

· Conveyor equipment

· Mixers

· High voltage switches

· Furniture industry

· Turnstiles and revolving doors

· Geared motors

· Winches

· Elevators

· Cranes

· Strap/belt tighteners

· Bucket conveyors

· Belt reversing locks

· Fans

· Automatic doors (subway)

· Fire damper flaps

· Aviation technology

· Roller plants

· Summer skiing

Indexing clutch

A repeated drive then idle motion will

be transferred to the driven side, step by

step, as rotary motion in one direction (the

clamping direction).

Application examples:

·Paper processing (advance)

· Seeding machines

· Staplers (staples)

· Conveyor belts (drive)

· Ratchets

· Ratchet wrenches

· Roller advance

· Installation tools

· Automation technology

Overrunning clutch

If the speed of the driven side exceeds the

speed of the driving side,the freewheel-clutch disengages the driving and driven sides by switching from torque transimit to idle.

Application examples:

·Copier machines

· Printing machines

· Conveyor equipment

· Transport equipment (speed matching)

· Starters for combustion engines

· Ergometers

· E-bikes

· Bicycle hubs

· Starters

· Emergency power aggregates

· Generators

· Hybrid applications (E-mobility)

· Palletizing and storage systems

· Model helicopters

· Hand operated sirens

· Roller coasters

· Washing systems

· Continuous ovens

· Compressors

· Compensating gearboxes

· Gas turbine drives

· Pump drives

· Belt drives

· Wheelchairs

Our advanges:

Our package:

R&B Certifications:

R&B MODELS:

1. One way clutch MG Series MG300/MG400/MG500/MG600/MG700/MG750/MG800/MG900/MG100/MG1100/MG1200/MG13

2. One way clutch MZ Series MZ15/MZ17/MZ20/MZ30-22/MZ30-25/MZ30/MZ35/MZ45-40/MZ45-40/MZ60-50/MZ60-55/MZ60/MZ70-65/MZ70

3. B200 series cam clutch

B203/B204/B205/B206/B207/B208/B209/B210/B211/B212/B213/B214

4. BB series one way bearings

BB15/BB17/BB20/BB25/BB30/BB35/BB40/BB15-1K-K/BB17-1K-K/BB20-1K-K/BB25-1K-K /BB30-1K-K/BB35-1K-K/BB40-1K-K/BB15-2K-K/BB17-2K-K/BB20-2K-K/BB25-2K-K /BB30-2K-K/BB35-2K-K/BB40-2K-K/

5. CSK series one way bearings

CSK8/CSK12/CSK15/CSK15-1K/CSK15-2K/CSK17/CSK17P/CSK17PP/CSK20/CSK20P/CSK20PP/CSK25/CSK25P/CSK25PP/CSK30/CSK30P/CSK30PP/CSK35/CSK35P/CSK35PP/CSK40/CSK40-1K/CSK40-2K/CSK8-RS/CSK35-2RS/CSK12-2RS/SK40-2RS/CSK15-2RS/CSK20P-2RS/CSK17-2RS /CSK25P-2RS CSK20-2RS/CSK30P-2RS CSK25-2RS /CSK30PP-2RS CSK30-2RS

6. GFK series one way clutch bearings

GFK20/GFK25 /GFK30 /GFK35 /GFK40/GFK45 / GFK50

7. DC series sprag freewheel cage one way clutch

DC2222G /DC2776/ DC2222G /DC3175 (3C) DC2776 /DC3175A DC3175 (3C) /DC3034/ DC3175A

DC3809A/ DC3034 /DC3809A(3C) /DC3809A /DC4127 /DC3809A(3C) /DC4127

DC5476A/ DC4972 (4C) /DC5476A (4C) /DC5476A/ DC5476B/ DC5476A

8. BWC BW. X.BWX series cam clutch

BW-13161/BW-13167/BW-13167MZ/BW-13214/BW-13214/BW-13231/BW-13243/BW-13244/BW-13255/BWC-13168/BWC-13219A/BWC-13229/BWX/BWC/X/RC series freewheel cage overrunning clutch

BWX134939/BWX13219/BWX132640/BWC13230/BWC13244/BWX132909/BWX133339/BWC13167/BWC13239/BWC13168/BWX13261/BWX133403 X133400B /X133400/ X133401 X133402 /X133403 X134398 /X134954/ X135005/ X135006/ X135036/ X135041/ X135052 /X135067 RC061008 /RC081208 RC101410/ RC121610

9. RSBW series one way clutches

RSBW25/ RSBW30/RSBW35/ RSBW40/RSBW45/RSBW50/RSBW55/RSBW60

RSBW65/RSBW70/RSBW75/RSBW80/RSBW85/RSBW90

10. PB series one way clutches

PB3/PB5/PB6/PB8/PB10/PB12/PB14

11. TSS Freewheels sprag one way clutch

TSS8/TSS10/TSS12/TSS15/TSS20/TSS25/TSS30/TSS35/TSS40/TSS45/TSS50/TSS60

12. TFS series cam clutches

TFS12/TFS15/TFS17/TFS20/TFS25/TFS30/TFS35/TFS40/TFS45/TFS50/TFS60/TFS70/TFS8/TFS90

13. AS(NSS or TSS)series one way clutch

TSS8 AS8 NSS8/ TSS10 AS10 NSS10/ TSS12 AS12 NSS12/TSS15 AS15 NSS15/

TSS20 AS20 NSS20/ TSS25 AS25 NSS25/ TSS30 AS30 NSS30/ TSS35 AS35

14. ASNU(NFS or TFS) series one way clutch

TFS12 ASNU12 NFS12/ TFS15 ASNU15 NFS15/ TFS17 ASNU17 NFS17/ TFS20 ASNU20NFS20/TFS25 ASNU25 NFS25/TFS30 ASNU30 NFS30/TFS35 ASNU35

15. NF roller type one way clutch

STIEBER NF8 GFRN55/STIEBER NF12 GFRN60 /STIEBER NF15 GFRN70/

STIEBER NF20 GFRN80/STIEBER NF25 GFRN90/STIEBER NF30 GFRN100

16. AE roller type one way clutch

STIEBER AE8/STIEBER AE12/ STIEBER AE15/ STIEBER AE20/ STIEBER AE25/ STIEBER AE30/ STIEBER AE35/ STIEBER AE40/ STIEBER AE45/ STIEBER AE50/STIEBER AE55/ STIEBER AE60/

17. AA roller type one way clutch

STIEBER AA20/ STIEBER AA25/ STIEBER AA30/STIEBER AA35 /STIEBER AA40/STIEBER AA45/ STIEBER AA50/STIEBER AA55/STIEBER AA60/STIEBER AA70/ STIEBER AA80/STIEBER AA90/

STIEBER AA100/ STIEBER AA120/ STIEBER AA150/

18.GFRGFRN series miler overrunning clutch

GFR12/GFR15/GFR20/ GFR25/GFR30/ GFR35/GFR40/GFR45/GFR50/GFR55/GFR60/GFR70

19.FE series freewheel one way clutch

FE448 /FE443 /FE422/FE423/FE428/FE427/FE432/FE433/FE453 /FE437

20. One way clucth CKA Series bearngs: CK-A1542/CK-A1747/CK-A2052/CK-A2562/CK-A3072/CK-A3580/CK-A4090/CK-A45100/CK-A50110/CK-A60130

21. Drawn cup needle Roller one way HF0406/HF0612/HF0812/HF1012/HF1216HF1416/HF1616/HF1816/HF2016/HF25

22.KI series:KI196

23.HYCS cam clutch :HYC8S/HYC10S/HYC12S/HYC15S/HYC20S/HYC25S/HYC30S/HYC35S/HYC40S/HYC45S/HYC50S/HYC60S

24.LD series one way clutch:LD04/LD05/LD06/LD07/LD08

25.MA series cam clutch:MA20/MA30

26.MI series cam clutch :MI300/MI400/MI500/MI600/MI700/MI750/MI800/MI900/MI1000/MI1100/MI1200/MI1300

27.MZEUseries one way cam clutch :MZEU12K/MZEU15K/MZEU20K/MZEU25K/MZEU30K/MZEU35K/MZEU40K/MZEU45K/MZEU50K/MZEU55K/MZEU60K/MZEU70K/MZEU80K/MZEU90/MZEU100/MZEU130/MZEU150

28.BR series cam clutch BR20/BR25/BR30/BR35/BR40/BR45/BR50/BR60/BR71/BR80/BR90/BR100/BR130/BR150/BR180/BR190/BR220/BR240/

29.BSEU cam clutch BSEU40-20/BSEU40-25/BSEU40-30/BSEU40-35/BSEU40-40/BSEU70-45/BSEU70-50/BSRU70-55/BSEU70-60/BSEU70-65/BSEU70-70/BSEU90-75/BSEU90-80/BSEU90-85/BSEU90-90

30.BST cam clutch BST30/BST50/BST65/BST75/BST85/BST95/BST110/BST135/BST160/BST200/BST220/BST250/BST270/BST300/BST335/BST350/BST425/BST450

31.HYC series

HYC8C/HYC12C/HYC15C/HYC17C/HYC20C/HYC25C/HYC30C/HYC35C/HYC40C/HYC45C/HYC50C/HYC60C/HYC70C/HYC80C/HYC90C

32. CLD series one way bearings CLD04-09-06/CLD04-10-16/CLD04-13-3.1/CLD06-12-06/CLD06-16-3.5/CLD08-16-5.5/CLD08-16-09/

34.AV series backstop one way clutch

STIEBER AV20,STIEBER AV25,STIEBER AV30,STIEBER AV35,STIEBER AV40, STIEBER AV45,STIEBER AV50,STIEBER AV55,STIEBER AV60,STIEBER AV70,

STIEBER AV80,STIEBER AV90,STIEBER AV100,STIEBER AV110,STIEBER AV120

35.RSCI series one way clutch

RSCI20/STIEBER RSCI25/STIEBER RSCI30/STIEBER RSCI35/STIEBER RSCI40/ RSCI45/STIEBER RSCI50/STIEBER RSCI60/STIEBER RSCI70/STIEBER RSCI80/ STIEBER RSCI80M/STIEBER RSCI90/STIEBER RSCI90M/STIEBER RSCI100/STIEBER RSCI100M/ STIEBER RSCI130/STIEBER RSCI180/STIEBER RSCI180M/STIEBER RSCI180II/ STIEBER RSCI180II-M/STIEBER RSCI220/STIEBER RSCI220M/STIEBER RSCI220II/ STIEBER RSCI220II-M/STIEBER RSCI240/STIEBER RSCI240M/STIEBER RSCI240II/ STIEBER RSCI240II-M/STIEBER RSCI260/STIEBER RSCI260M/STIEBER RSCI260II/ STIEBER RSCI260II-M/STIEBER RSCI300/STIEBER RSCI300M/STIEBER RSCI300II

36.RSBI series

RSBI60/RSBI70/RSBI80/RSBI90/RSBI100/RSBI130/RSBI150/RSBI180/RSBI190/RSBI220/RSBI240STIEBER/RSBI100 /RIZ100G4 /STIEBER RSBI130 /RIZ130G4 /STIEBER RSBI150 /STIEBER RSBI100F8 RIZ30G7 /STIEBER RSBI130F8/ RIZ35G7 STIEBER/ RSBI150 F8 RIZ40G7

Needle roller bearings:

1. K series radial needle roller and cage assembiles,

NK series, Non-inner ring needle bearing, light series

NKS, Non-inner ring needle roller bearings, heavy series

RNA49, Non-inner needle roller bearing, sizes 49 series

RNA69, Non-inner needle roller bearings, size 69 series

RNA48, Non-inner needle roller bearings, size 48 series

NKI, with inner ring needle bearings, light series

AXK thrust ball bearing with flat seat.

2. Supporting roller and curve roller bearings:

NUTRseries, NUKRseries, KR series, PWKR series, NATR series, RSTOseries, STOseries, NATV series, CF series.

3. Combined radial bearings:

NKIA series, NKIB series, NX series, NKX series, NKXR series, ZARN series, ZARF series, RAXF series

Transport ways:

Easy communication ways:

FAQ

A:Will you send me free sample?

B: It is highly encouraged to ask for the samples for quality check.

A:Do you like to serve the client only with small orders?

B:We enjoy to grow up together with all our clients whatever big or small.And WIN-WIN is our objective.

A:Could you accept OEM and customize?

B:YES, we can customize for you according to sample or drawing, but, pls provide us technical data, such as dimension and mark.

A:Is it your company is factory or Trade Company?

B:We have our own factory; our type is factory + trade.

A:How to maintain my bearings?

B:a. Soak your bearings in mineral spririts or paint thinner to remove any grease or particulates;

b. Blowbearing out with compressed air;

c.place a light drop of oil on the bearing;

d.If the bearings feel rough repeat, give the bearing a spin.

A:Could you supply door to door service?

B:Yes, by air and by express (DHL, FEDEX, TNT, ARAMEX,EMS, SF)

Our Advantages

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!